One blade rip saw rip line 160

Contattaci per il prezzo

Description

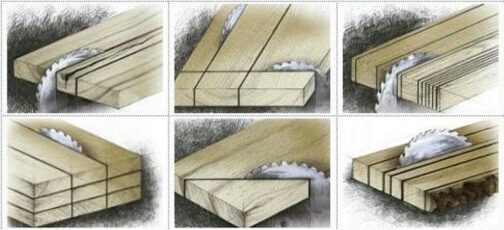

Modern processing technology of solid wood with using one blade rip saw RIP LINE 120 (RIP LINE 160) significantly increases yield and productivity and values the quality of wood material. Emphasis on the cut quality and simplicity of service is a matter of fact.

Highly universal saw RIP LINE 120 (RIP LINE 160) finds application mainly in small and medium-sized plants. The RIP LINE 120 (RIP LINE 160) can cut prisms, planks, beams and large-area material. Input materials can be plastered, trimmed, formatted and it is possible to produce cardboard plates and lamellae. It can be cut at an angle and miter.

The advantage of the machine is high speed and accuracy of cuts and high degree of flexibility of input and output dimensions of the processed material. RIP LINE 120 (RIP LINE 160) is valued in furniture workshops, production of semi-finished products for windows, doors and stairs.

The machine can be also used for cutting non wood materials, e.g. polyurethane panels, sandwich panels, plastic plates, aluminum plates, etc.

Of course there are security features that ensure security of work on the rip saw. The machine fulfills the strictest demands on security of work follows from relevant EC regulations and directives.

TECHNICAL DATA

Engine 11 kW or15 kW, 2900 rev/min.

Cut height standard 0 – 120 mm (0 – 160 mm)

Saw blade Ø 450 – 550 mm (FLS 160 ECO 450 – 550 mm)

Inner Ø of a saw blade Ø 80 mm

Speed feed into the cut 0 – 60 m/min, infinitely adjustable

Cut length standard 3,2 m – 6,2 m

Cut width standard 420 mm (450 mm)

Working height 850 ± 50 mm

Outer dimensions Length = cut length + 1800 mm

Exhaust tunnel duct Ø 2 x 160 mm

Exhaustion speed 25 – 30 m/s