Optimising cross cut saw opt 900 easy cut

Contattaci per il prezzo

Description

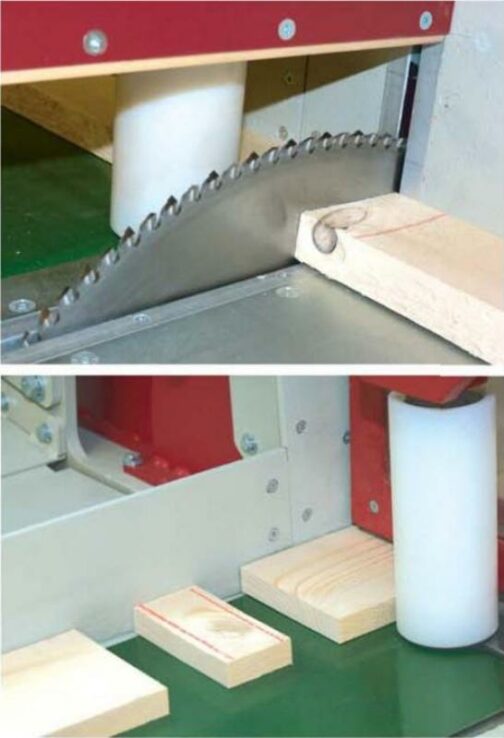

Optimizing cross cut saw KP 900 Easy Cut is designed for companies that process solid wood and put maximum emphasis on quality and yield of their production. Optimizing cross cut saw KP 900 Easy Cut is used for cutting out defects and optimizing fixed lengths of blades in the production of wood blocks, boards, massive furniture parts, floors, floor boards, planks, packages, etc. Of course there are security features that ensure security of work on the rip saw. The machine fulfills the strictest demands on security of work follows from relevant EC regulations and directives.

FEEDING DEVICE

Length of the feeding device (input table) – according to the customer’s request (3,2 m – 7,2 m).

Drive unit AC SERVO – high precision, long service life, minimum noisiness.

Linear feed of the travel carriage integrated on the solid closed profile, pushing foot with reverse travel, durability, easy maintenance.

Continuous feed speed 0 to 2 m/s, reverse speed max. 3 m/s.

Optional side pressure input / output.

Sufficient performance of the feeder for heavy sections.

Automatic checking of the entry length of wood.

Auto start feed of the loader.

Lateral tilt of the input table 8°

SAW

Saw blade disc 350 mm – 600 mm (according to the version standard/max)

Engine power 5.5 kW (7.5 optional)

Saw feed speed into the cut continuously regulated

Maximum cutting speed 0.1 s

Upper pressure of cut piece

Maximum accuracy tolerance ± 0.3 mm (± 0.1 mm optional)

Control panel – color LCD Touch Screen 15 “

Soundproofed box design

SM Optimal Control Software

Lateral tilt table of cross-cut unit 8 °

OUTPUT CONVEYOR BELT – SORTER

Conveyor length for timber sorting (according to the customer’s requirement)

Pneumatic product range sorters – ejectors

Programmable sorting of individual lengths

Lateral tilt of sorting belt 8°

TECHNICAL DATA

Overall electrical input 8 kW

Connection 3×380 V/50Hz

Air connection 8 bar (0,8 Mpa)

Air consumption 200 l/min.

Operator 11 employee input + 1 output

Dimensions See appendix

Weight 1400 kg

Extraction Recommended FT 402 – 2×120 mm 30 m/s