Straightening/Profiling machine Scm Super Program 4

Contattaci per il prezzo

Description

STRAIGHTENING – PROFILING MACHINE SUPER PROGRAM 4

STANDARD EQUIPMENT

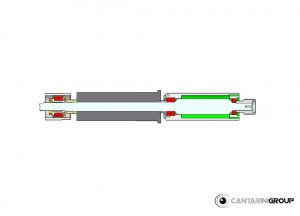

Horizontal spindles counter-supported

Electronic control 6 axes / 7 axes (it depends on model)

Pneumatic pre-planer roller with exclusion on control panel

Pneumatic pressure on drive units

Manual lubrication of the worktable

Manual centralized lubrication of guides

Manual centralized lubrication of vertical spindles

Basement tables in Hardox HB400

Additional drive spindle

Blowers on the table to optimize wood sliding

Indipendent motor unit on each work unit

Each tool holder shaft is equipped with an independent motor

Poly-V belts drive on all spindles, they bear the best efficiency of motors power

Drive system operated by gearcases

TECHNICAL FEATURES

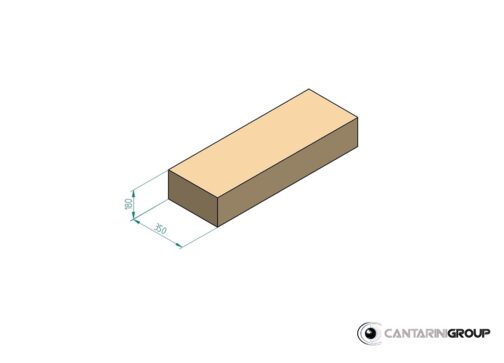

Max working width (with tools dia. 125mm) 350 mm

Min working width (with tools dia. 125mm) 25 mm

Max working height (with tools dia. 125mm) 180 mm

Min working height (with tools diam. 125mm) 12 mm

Max working length universal spindle 230 mm

Max working length universal spindle like upper spindle 190 mm

Feed speed with inverter 4-30 m/min

Spindle speed 6000 g/1′

Vertical and horizontal spindles diam. 40

In feed table length 2500 mm

Motor power lower and upper spindle HP20 – kW 15

Motor power vertical spindles HP12 – kW 9

Motor power 2° lower/upper spindle HP12 – kW 9

Motor power universal spindle HP10 – kW 7,5

Automatic star/Y start Standard

Axial adjustment of vertical spindles 75 mm

1° unit tool diameter 125 mm

Min. and max. diam. for all spindles cutters (except 1° unit and universal) 110 – 230 mm