Minimax ME 20 edgebander

Contattaci per il prezzo

Edgebander equipped with manual lifting of the feeder with automatic positioning of the operating groups synchronized with the feeder and according to the height of the panel.

Description

Minimax ME 20 edgebander

Minimax ME 20 edgebander technical data

- worktop dimensions [mm] 1950 x 180

- worktop height [mm] 904

- edge thickness in roll [mm] 0,4 ÷ 2

- max. thickness of the edges in strips [mm] 5

- workable panel height min. ÷ max. [mm] 12 ÷ 50

- length / width min. panels with roll edge [mm] 180/65

- length min. panel headed only in front [mm] 120

- drive motor power S1 [kW] 0.25

- feed speed [m / min] 6

- pneumatic system pressure [bar] 6.5

- working temperature [° C] 190

- extractor hood (base) diameter [mm] 120

- suction hood (glue pot) diameter [mm] 60

Minimax ME 20 tubular edge-glueing unit

- motor power S1 [kW] 0.18

- glue capacity [kg] 0.5

Minimax ME 20 edge trimming unit

- motor power S1 [kW] 0.55

- widia cutters Ø 75 mm Z4

- cutter rotation speed [rpm] 12,000

Minimax ME 20 edgebander general features

- monobloc steel base to ensure stability, rigidity and maintenance of adjustments

- anti-friction sliding surface with n. 3 rollers on the table

- user-friendly control panel in all working conditions

- panel transport system via upper feeder with high grip toothed belt, with steel cables inside

- manual lifting of the feeder with automatic positioning of the operating groups

- synchronized with the feeder and based on the height of the panel

- numeric indicator of the selected panel thickness

- panel support roller on the whole length of the machine

- exit guide in anodized aluminum

- dedicated suction of glue fumes; centralized aspiration of other residues

protection cabin - electrical system with PLC, padlockable main switch and thermal relays

emergency button

Glue tank unit, edge loading and pressure complete with:

- hot melt glue tank with rapid and teflon-coated heating, for an easy glue change

- belt spreading roller with internal resistance to guarantee a constant glue temperature

- temperature control of the applied glue integrated in the PLC

- device for automatic recovery of unused glue

- automatic loader for edges in rolls with cutter for edges up to 2 mm thick

- revolving roll holder diameter 730 mm

- pressure roller with two rollers: one in rubber, the other in steel

- adjustment of the incoming guide according to the thickness of the edge with movement through

- numerical indicator

- function integrated in the PLC for the reduction of the glue pot temperature after a temporary inactivity

Minimax ME 20 edge banding unit

- Pneumatic piece trimmer for cutting the edge at the front and rear of the panel at 90 °. Possibility to exclude the group via PLC.

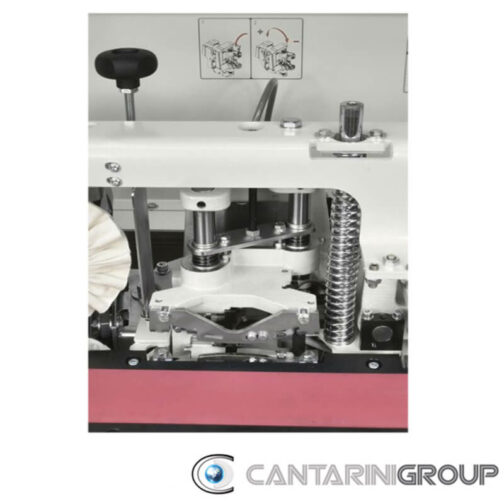

Stacked trimming unit

- Vertical skid copiers to perfectly align the tools at the work point

- The unit is complete with 72 mm diameter cutters combined

- The radial part of the cutting edge is used to trim radiated edges (2 mm) and thin rounded edges. The straight part of the cutting edge is used for trimming wooden edges up to 5 mm. To move from the radius edge or wooden edge position it is sufficient to move the drills axially. The thickness is indicated by 2 numerical indicators

Optional

- Single-phase 50 Hz version

- Single-phase 60 Hz version

- Triple wall packaging

Follow us on our Facebook page!