Optimising saw opt 500

Contattaci per il prezzo

Description

Optimizing cross-cut saw KP 500 Optim is designed for woodworking companies, which process massive wood and put maximum emphasis on the quality and yield of their production. Optimizing saw KP 500 Optim is used for cutting out defects and optimizing fixed lengths of blades in the production of glued blocks, boards, massive furniture parts, floor, floor boards, boards, packages, etc. Of course there are security features that ensure security of work on the rip saw. The machine fulfills the strictest demands on security of work follows from relevant EC regulations and directives.

FEEDING DEVICE

Length of the feeding device 4,2 m, 6,2 m (smooth metal table without rollers)

Left version of the machine (material input from the right side)

Maximum weight of processed material at the input 75 kg

Forward feed speed of pusher 1,5 m/s

Tolerance of max. accuracy +/- 0,3 mm

Reverse speed of the loader (material loading) max. 2 m/s

Time for positioning and the cut – about 2,4 sec

Material feeding – open aluminum axis with linear lead, feeding by toothed belt 50 mm, servo-drive + planetary gearbox

Pneumatic lifting pusher for reading material length and reading of material defects

automatic start of the feed of the loader

Input pneumatic lever pressure

Tilt of input table 8°

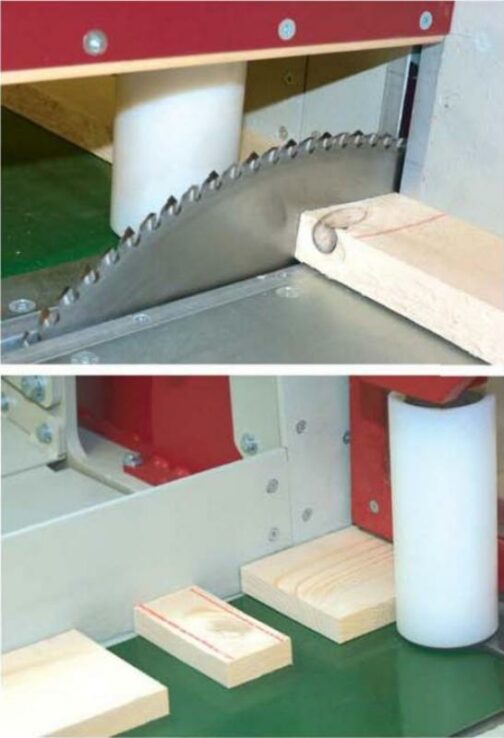

SAW

Power of main motor 5,5 kW (7,5 kW optional)

Transfer of torque on the shaft by toothed belt of the width 30 mm

Saw blade diameter 500 mm (550 mm)

Dynamic lift of the blade to cut by pneumatic cylinder

Continuous regulation of speed and cutting height

The upper pressure of cut piece

Output rolling pressure is optional

Selection of an activation and deactivation of the input pressure (output pressure is optional)

Safety – covering of area of cross-cut unit

Side tilt table of cross-cut units 8 °

Control panel – color LCD Touch Screen 15“

Soundproofed cabinet design

SM OPTIMAL control software

OUTPUT TABLE, BELT CONVEYOR

Sheet metal hard smooth table of the length of 2 000 mm

Sorting conveyor of length of 3 m, 4 m, 6 m, 8 m is optional

Pneumatic sorters of the assortments – ejectors

Lateral tilt of the output table or sorting belt 8°

TECHNICAL DATA

Overall electrical input 8 kW

Connection 3 x 380V / 50Hz

Air connection 8 bar (0,8 MPa)

Air consumption 500 l/min. (depends on the number of cuts and ejectors)

Weight 800 kg

Extraction 1 x 120 mm, 25 – 30 m/s