Vertical panel saw kgs/ gmc program m10

Contattaci per il prezzo

Description

AUTOMATIC PANEL SAW IN THE VERTICAL CUTS WITH ELECTRONIC PROGRAMMER M10 FOR HORIZONTAL CUTS, TOWING WITH BRUSHLESS MOTORS AND ADVANCEMENT ON LINEAR GUIDES

The main components of the frame, machined on CNC machine tools allow dimensional accuracy in phase of assembling, therefore an excellent precision while using the machine. Movements on vertical and horizontal axes are secured by hardened and ground linear guides on which slide linear motion guides that allow an high smoothness of the saw-group without clearances. Brushless motors for the vertical and horizontal feed provide speed in travel and accuracy in positioning. The standard version of the machine offers the turning of the saw-head, the in-feed of the blade and the locking of the axis fully automatic. The mobile panelled frame (powered by an electric actuator) and the rollers for the raising and sliding of heavy panels, are both standard.With the vertical panel saw PROGRAM M10 is possible to store up to 400 programs, each containing up to 30 different cutting lines repeatable 99 times.

TECHNICAL DATA

Length horizontal cut 4300 mm /5300 mm

Height vertical cut 2200 mm

Max height horizontal cut 2100 mm

Max height vertical milling 2200 mm (*2080mm)

Cutting thickness 80 mm

Motor power 7,5 hp

Diameter main blade 300 mm

Revolutions of main blade 5200 rpm

Milling diameter 250 mm (*110 mm)

Revolutions of milling 5200 rpm (*8000)

Gross weight frame cages packing 860 kg

Gross weight beam cages packing 800 kg

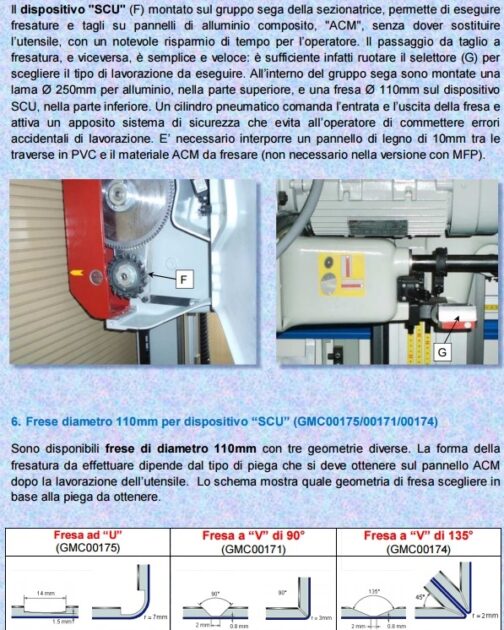

* with SCU device

PROGRAMMER CHARACTERISTICS

400 programs, each containing up to 30 different cutting lines repeatable 99 times.

Vertical and horizontal Towing by brushless motors and linear guides hardened and grinded.

Double work camp. Automatic search of vertical cutting positions.

STANDARD ACCESSORIES

Brushless motor vertical towing 1200 Watt – Brushless motor horizontal towing 1200 Watt

Paneling mobile device “MFP”

Pneumatic lifting rollers

Electronic display of measurement for vertical cuts

Right side duct for dust collection horizontal cuts

Blade HM Z 48 (mounted)

Suction pipe diam. 100 with chain cable carrier

Retractable tilting intermediate supports for the whole length of cut

No.3 measurement stops for vertical cuts

Pneumatic lock of the carriage saw

Saw unit rotation 90° in automatic with manual control

Linear guides for axis X and Y

Blocking beam with safety micro with automatic research

Pneumatic entry of the blade – speed control advancement with inverter (3/25 mt/m’)

Service keys

Instruction manual